Critical Parts &

Components for your

Processing Equipment

Brighton Parts (formerly Enerfab PCG), a division of Brighton Tru-Edge and a member of the Enerfab family of companies, is your go-to solution for all replacement parts and components for Enerfab and Brighton fabricated process equipment as well as the exclusive provider of Hamilton Kettle parts and components.

The level of quality and care you’ve come to expect from Enerfab and Brighton custom fabricated solutions extends to the very last detail of your process equipment, right down to the replacement gaskets, manways, and other critical parts needed to get your equipment back up and running.

Brighton’s aseptic technology ensures end-product sterility and safety on replacement parts for Enerfab-designed aseptic systems.

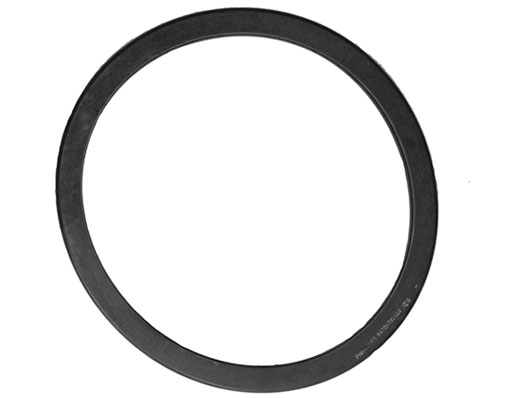

- Viton & silicone gaskets

- O-Rings

- Filters

- Sight glasses

Easy-to-clean gaskets critical to the containment of your tank, reactor, and piping that provide lasting durability and clean-ability.

- L and U shaped gaskets

- Available in Nitrile, White, and Black Natural Rubber

- Customized options available for your unique environment

Brighton Parts is the exclusive supplier of replacement and repair parts for Hamilton Kettles’ complete line of standard steam jacketed kettles, mix cookers and custom-fabricated cooking vessels.

Brighton’s aseptic technology ensures end-product sterility and safety on replacement parts for Enerfab-designed aseptic systems.

- Viton & silicone gaskets

- O-Rings

- Filters

- Sight glasses

Need Help?

Complete the form below or contact our team at Brighton for help finding the right parts for your equipment.